Introduction to Manual Transmission Wear and Tear

How to identify signs of wear and tear in a manual transmission – A manual transmission, also known as a standard transmission, is a type of gearbox that allows a driver to manually select the gear ratios for the engine. This differs from an automatic transmission, where the gear selection is automatic. Manual transmissions are renowned for their fuel efficiency and the driver’s direct control over the vehicle’s acceleration and response.

However, the mechanical components are subject to wear and tear, which can lead to performance degradation and potentially costly repairs if ignored.Identifying the early signs of wear and tear is crucial for maintaining optimal performance and avoiding significant future problems. Proactive maintenance, informed by these signs, can extend the lifespan of the transmission and save significant money in the long run.

This section will Artikel the key components susceptible to wear, and the typical signs of wear and tear associated with different manual transmission types.

Key Components Susceptible to Wear

Manual transmissions consist of numerous interconnected components, each playing a critical role in power delivery and gear shifting. These components, due to their constant engagement with friction, are especially vulnerable to wear and tear. Significant wear can affect the smooth operation and durability of the transmission, so early detection is crucial. Common components susceptible to wear include:

- Gear teeth: The teeth on gears within the transmission are crucial for transferring power. Repeated engagement and disengagement can cause wear, leading to noise, rough shifting, and eventual gear failure. For example, frequent use of the clutch at high RPMs can significantly accelerate gear tooth wear.

- Clutch components: The clutch system is vital for connecting and disconnecting the engine from the transmission. The clutch disc, pressure plate, and release bearing experience friction and wear during operation, particularly during aggressive driving. Signs of wear may include a slipping clutch or difficulty engaging gears.

- Synchronizers: Synchronizers are designed to match the speed of the input and output shafts before engagement, ensuring smooth shifting. Wear in synchronizers can lead to rough or hesitant shifts, particularly at lower speeds. For example, frequent shifting under heavy load can accelerate synchronizer wear.

- Bearing and shafts: Bearings and shafts facilitate smooth rotation of gears and components. Worn bearings can lead to noise and vibrations during operation. Shafts experience wear through continuous rotation and are vulnerable to damage from impact.

- Shift forks and linkages: These components are responsible for shifting between gears. Worn or damaged shift forks can lead to rough or difficult shifts. Similarly, damaged linkages can lead to issues with gear selection.

Importance of Early Detection

Early detection of wear and tear is crucial for several reasons. It allows for timely repairs, prevents catastrophic failure, and maintains optimal vehicle performance. Ignoring the signs can result in expensive repairs, reduced fuel efficiency, and potential safety hazards. Early intervention can often prevent costly transmission replacements, while proactive maintenance significantly extends the lifespan of the transmission.

Common Manual Transmission Types and Wear Patterns

The following table Artikels common manual transmission types and their typical wear and tear patterns, emphasizing the components and signs associated with potential damage:

| Transmission Type | Component | Sign of Wear | Potential Damage |

|---|---|---|---|

| Manual 5-speed | Clutch | Clutch slipping, difficulty engaging gears | Clutch replacement, transmission damage |

| Manual 6-speed | Synchronizers | Rough or hesitant shifting, especially at low speeds | Synchronizer replacement, transmission overhaul |

| Manual 6-speed | Gear Teeth | Grinding noise during gear changes | Gear replacement, potential transmission failure |

| Manual with Overdrive | Overdrive gear | Difficulty engaging overdrive | Overdrive gear replacement, transmission overhaul |

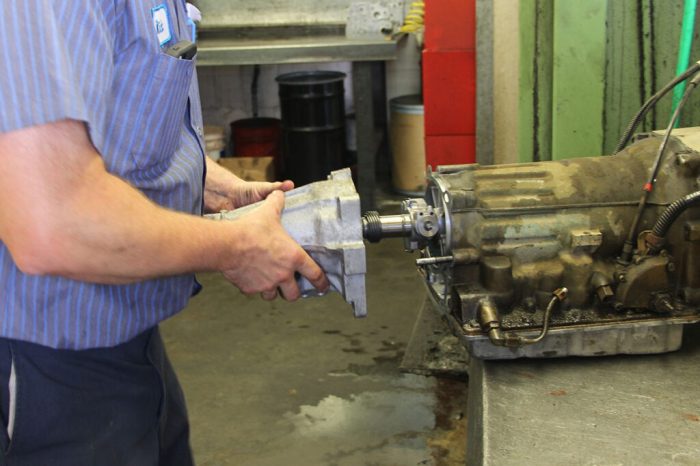

Visual Inspection Methods

Source: metrotransmission.com

Visual inspection is a crucial initial step in diagnosing manual transmission wear and tear. It allows for a quick assessment of visible components and potential issues without the need for extensive disassembly. This method is highly effective in identifying early signs of problems, enabling timely maintenance and preventing more serious damage.

Gear Engagement Inspection

Proper gear engagement is essential for smooth shifting and optimal performance. Inspecting the gear engagement process involves observing how gears mesh during shifting. Notice any unusual noises, such as grinding or clicking sounds. A smooth, positive engagement indicates good gear condition. Conversely, rough engagement, or noises, suggest potential issues with gear teeth, misalignment, or wear.

Pay close attention to the feel of the shift lever, noting any resistance or unusual movement.

Shifter Operation Inspection

The shifter’s operation should be smooth and precise. Assess the movement of the shifter through each gear. Any sticking, binding, or unusual resistance in the movement of the shifter are warning signs. Note the play in the shifter and how it feels as you move through the gears. A stiff or unusually loose shifter can point to problems with the shift linkage or the internal components of the transmission.

Transmission Housing Damage Inspection

Visual inspection of the transmission housing is crucial for identifying potential damage. Look for any cracks, dents, or unusual bulges on the housing. Examine the exterior of the transmission housing for any signs of leaks, especially fluid leaks. These signs can indicate internal damage or wear and tear. A leak could point to a damaged seal, gasket, or even a cracked housing.

Clutch System Inspection

A step-by-step guide for visually inspecting the clutch system is provided below:

- Examine the Clutch Pedal: Check for excessive play or unusual resistance in the clutch pedal movement. Note the feel of the pedal and how it engages with the clutch mechanism.

- Inspect the Clutch Housing: Carefully inspect the clutch housing for any cracks, damage, or unusual wear patterns. Pay attention to the areas where the clutch disc and pressure plate are mounted.

- Look for Leaks: Examine the clutch system for any signs of leaks. Fluid leaks can point to problems with the clutch hydraulic system or seals.

- Assess the Clutch Disc: If possible, inspect the clutch disc for any signs of excessive wear, damage, or friction material deterioration. Note any unusual discoloration or deformation.

Visual Inspection Tools

The following table Artikels common visual inspection tools and their applications, along with safety precautions.

| Tool | Description | Application | Safety Precautions |

|---|---|---|---|

| Flashlight | Provides focused light for inspection in dark or tight areas. | Inspecting under the vehicle, checking for leaks, or examining hard-to-reach components. | Handle with care to avoid dropping it on the ground or into tight spaces. |

| Magnifying Glass | Enhances visibility for detailed inspection of small parts. | Examining gear teeth, clutch disc, or other small components for signs of wear. | Use with caution to avoid scratching or damaging delicate parts. |

| Gloves | Protects hands from potential hazards during inspection. | Handling parts or tools in potentially dirty or greasy environments. | Choose appropriate gloves for the specific task. |

| Safety Glasses | Protects eyes from flying debris or particles during inspection. | Inspecting components that may generate sparks or small particles. | Wear safety glasses whenever there is a potential for eye injury. |

Listening for Unusual Sounds

Listening attentively to the sounds emanating from your manual transmission can reveal potential wear and tear issues long before they escalate into major problems. A keen ear can identify subtle changes that might otherwise go unnoticed during a visual inspection. This proactive approach allows for timely repairs and prevents costly breakdowns.Identifying the source of unusual sounds is crucial for effective troubleshooting.

Pay close attention to the context in which the noise occurs – acceleration, deceleration, idle speed, gear changes, or under load – as this information helps pinpoint the affected component. The intensity and pitch of the sound are also valuable indicators of the severity of the issue.

Common Transmission Sounds and Potential Causes

Careful listening to your manual transmission can reveal potential wear or damage. Understanding the different sounds and their possible causes is essential for timely maintenance. The following table provides a concise comparison of typical transmission sounds to potential causes, severity, and recommended actions.

| Sound Description | Potential Cause | Severity | Action |

|---|---|---|---|

| High-pitched whine or screech, especially noticeable under load | Worn or damaged synchronizers, worn bearings, or a damaged or worn-out gear | Moderate to Severe | Consult a mechanic immediately. A damaged gear may lead to a complete transmission failure. |

| Grinding or scraping sound during gear changes | Worn-out or damaged synchronizers, or improperly aligned gears | Moderate to Severe | Consult a mechanic immediately. This could indicate damage to synchronizers or other internal components. |

| Loud clunking or banging sound, especially during gear shifts | Worn-out or damaged shift forks, bushings, or linkage | Moderate to Severe | Consult a mechanic to address the worn-out components. |

| Metal-on-metal scraping sound | Worn bearings, loose components, or damaged gears | Severe | Immediate professional attention is needed. |

| Whining or humming sound that increases with speed | Worn bearings or shafts | Moderate | Schedule an inspection with a qualified mechanic. Addressing this promptly can prevent more significant damage. |

| Loose rattling sound | Loose parts, such as bolts, or improperly tightened parts | Minor | Tighten any loose bolts or components to address the issue. |

Noises to Ignore

Some sounds, while noticeable, are not necessarily indicative of serious transmission problems. Understanding these benign sounds helps avoid unnecessary worry and costly repairs.

- A slight clicking sound during gear changes, especially in cold weather, is often normal and does not indicate an immediate issue.

- A minor humming or vibrating sound at idle speed is often normal and doesn’t necessitate immediate action.

- A light tapping or ticking sound during acceleration, often accompanied by vibrations, can be attributed to the operation of the clutch, and does not always indicate a transmission issue.

- A gentle whirring sound during operation is often normal for a manual transmission.

Checking Fluid Levels and Condition: How To Identify Signs Of Wear And Tear In A Manual Transmission

Proper maintenance of a manual transmission relies heavily on monitoring the transmission fluid. This fluid is crucial for lubrication and cooling, ensuring smooth gear shifts and extending the transmission’s lifespan. Inspecting the fluid’s level, color, and consistency is a vital part of routine maintenance.Understanding the condition of the transmission fluid is essential to identifying potential problems early. Degraded fluid can lead to friction, overheating, and ultimately, transmission failure.

Regular checks allow you to address issues proactively and prevent costly repairs.

Checking Transmission Fluid Level

The transmission fluid level is typically checked with the vehicle parked on a level surface. Consult your vehicle’s owner’s manual for the specific procedure, as it may vary slightly depending on the make and model. A dipstick is typically used to determine the fluid level. Ensure the engine is cool before performing the check. The dipstick should be wiped clean before insertion to prevent inaccurate readings.

Insert the dipstick fully, then remove it and examine the fluid level. The level should be within the specified range indicated on the dipstick.

Inspecting Transmission Fluid Color

The color of the transmission fluid provides a visual indicator of its condition. New fluid is typically a reddish-brown or amber color. A significant change in color, such as darkening or becoming grayish-black, suggests contamination or degradation. Darkened fluid may indicate the presence of metal particles, wear, or overheating. A milky appearance can point to water contamination.

This should be investigated further.

Assessing Transmission Fluid Smell

The smell of the transmission fluid is another valuable diagnostic tool. Fresh fluid typically has a mild odor. A burnt or acrid odor suggests overheating or internal component friction, which warrants immediate attention. If the fluid smells like something other than a mild odor, such as burnt rubber, investigate further. A strong odor is an indication of potential problems.

Understanding Fluid Level, Color, and Consistency

The transmission fluid level, color, and consistency are all interconnected indicators of the transmission’s health. A low fluid level can lead to overheating and damage. Darkened or discolored fluid indicates wear and tear, potential contamination, or overheating. A thick or sticky consistency suggests fluid degradation. These issues often manifest as difficulty shifting gears, a grinding noise, or a burning smell.

The fluid’s viscosity (thickness) also matters; it should be within the manufacturer’s specifications.

Disposing of Used Transmission Fluid

Proper disposal of used transmission fluid is crucial to environmental protection. Used transmission fluid is considered hazardous waste and should never be poured down the drain. Consult local regulations and guidelines for the safe disposal of used transmission fluids. Contact your local waste disposal authority or recycling center for information on appropriate disposal methods. Follow these procedures to protect the environment.

Comparison of Transmission Fluid Types

| Fluid Type | Viscosity | Color | Application |

|---|---|---|---|

| Dexron VI | Medium | Reddish-brown | Automatic transmissions |

| Mercon LV | Medium | Reddish-brown | Manual transmissions |

| ATF | Medium | Amber | Automatic transmissions |

| Mercon V | Medium | Reddish-brown | Manual transmissions |

This table provides a general overview of common transmission fluid types, their viscosities, and typical colors. Always refer to your vehicle’s owner’s manual for specific recommendations.

Operating the Transmission Through its Range

Source: carnewsbox.com

Thorough examination of a manual transmission goes beyond visual inspection and listening for sounds. Actively operating the transmission reveals crucial details about its condition and potential issues. This involves testing each gear for smooth operation and evaluating clutch engagement and shifting mechanics. Properly evaluating these aspects is vital for identifying wear and tear that may lead to costly repairs.

Testing All Gears for Smooth Operation, How to identify signs of wear and tear in a manual transmission

Testing all gears is essential for determining smooth operation and potential issues. Each gear should engage without hesitation or excessive play. Gradual and consistent engagement is a sign of proper wear and function. Conversely, jerky engagement or difficulty in shifting indicates possible issues with synchronizers, bearings, or other components.

Identifying Clutch Engagement Issues

Clutch engagement issues manifest in various ways. A slipping clutch, characterized by a loss of power transfer, is a clear sign of wear. Excessive play in the clutch pedal, which may feel spongy or unresponsive, also indicates potential problems. A grinding or dragging sound during engagement can suggest clutch plate wear, or issues with the pressure plate or release bearing.

Identifying Gear Shifting Issues

Gear shifting issues are often accompanied by symptoms like difficulty in shifting, a harsh or noisy shift, or a complete inability to shift into a particular gear. The gear shift mechanism, if not functioning correctly, can lead to a noticeable loss of smoothness. A noisy shift can often be traced to worn synchronizers, damaged gear teeth, or issues with the shift fork.

Actions to Take While Testing the Transmission

- Engage each gear progressively, noting any resistance, play, or unusual sounds. A consistent and smooth transition through each gear is a positive sign.

- Observe the clutch pedal for play or responsiveness. A spongy or unresponsive pedal can indicate issues with the clutch system.

- Listen carefully for any unusual noises during shifting, such as grinding, clicking, or dragging. Unusual noises often point to specific parts wearing down.

- Note the feel and responsiveness of the gears. A noticeable difference in the feel when shifting from one gear to another is an indication of wear or malfunction.

Symptom Table for Transmission Issues

| Gear | Issue | Symptoms | Possible Cause |

|---|---|---|---|

| 1st | Difficulty engaging | Jerky engagement, resistance, grinding sound | Worn synchronizer, damaged gear teeth |

| 2nd | Slipping | Loss of power transfer, lack of responsiveness | Worn clutch plates, damaged clutch pressure plate |

| 3rd-5th | Harsh Shifting | Loud noises, resistance, sticking | Worn synchronizers, damaged gear teeth, worn shift forks |

| Reverse | Inability to engage | No engagement, resistance, clicking sound | Damaged reverse gear, worn reverse synchronizer |

Understanding the Role of Lubrication

Proper lubrication is critical for the smooth and long-lasting operation of a manual transmission. It reduces friction between moving parts, preventing wear and tear, and maintaining optimal performance. Adequate lubrication allows components to function efficiently and minimizes the risk of premature failure.Lubrication acts as a protective barrier against metal-to-metal contact, reducing friction and heat buildup. Without sufficient lubrication, components rub against each other, generating excessive heat and leading to rapid wear and potential damage.

This can manifest in various ways, from noisy operation to complete failure. The correct type and amount of lubricant are crucial for maintaining the transmission’s health.

Importance of Proper Lubrication

Lubrication is paramount in manual transmissions, as it directly impacts the longevity and performance of the system. Proper lubrication minimizes friction between gears, shafts, and bearings, ensuring smooth shifting and preventing premature wear. This reduction in friction also translates to reduced energy loss and improved fuel efficiency. Proper lubrication safeguards components from excessive heat generation, a significant contributor to component failure.

Effects of Inadequate Lubrication

Inadequate lubrication can lead to significant issues within the transmission. Without sufficient lubrication, gears and other components rub against each other, creating friction and heat. This excessive heat can cause metal fatigue, leading to pitting, scoring, and eventual component failure. Moreover, insufficient lubrication can lead to seizing, which completely disables the transmission. The consequences can range from minor operational issues to complete failure.

Role of Oil Viscosity in Transmission Performance

The viscosity of the transmission oil significantly impacts its performance. A proper viscosity allows the oil to effectively coat all moving parts, minimizing friction. Too thin an oil may not provide adequate lubrication, while too thick an oil can impede the movement of parts. The correct viscosity is crucial for optimal performance and extended transmission life. Manufacturers specify the recommended viscosity for each transmission type to ensure proper operation and longevity.

Lubrication Points in a Manual Transmission

Several critical points within the manual transmission require proper lubrication. These include the gear teeth, the bearings, and the shafts that transmit power. Proper lubrication ensures these components receive the necessary protection from wear. Failure to adequately lubricate these points can lead to premature wear and tear and eventual transmission failure.

- Gear teeth: Lubrication is essential for the smooth engagement and disengagement of gears, preventing friction and heat buildup.

- Bearings: Bearings require lubrication to reduce friction and maintain proper alignment. Proper lubrication prevents excessive wear and ensures smooth rotation.

- Shafts: Shafts, which transmit power throughout the transmission, need lubrication to reduce friction and prevent heat build-up. Lubrication is vital for their long-term operation.

Effects of Different Lubrication Levels on Transmission Performance

The table below illustrates the effects of different lubrication levels on transmission performance, component wear, and potential damage. Maintaining the correct oil level is essential for optimal performance and longevity.

| Lubrication Level | Performance | Component Wear | Possible Damage |

|---|---|---|---|

| Adequate | Smooth shifting, quiet operation | Minimal wear | None |

| Low | Rough shifting, increased noise | Increased wear on gears and bearings | Possible gear damage, bearing failure |

| High | May lead to dripping or leakage | Potential for excessive lubrication, minimal wear | None, unless excessive |

Illustrative Examples of Wear and Tear

Source: saymedia-content.com

Identifying the specific signs of wear and tear in a manual transmission is crucial for timely maintenance and avoiding costly repairs. This section provides clear examples of mild, severe, and common damage scenarios, enabling you to recognize potential issues in your transmission.

Mild Wear and Tear Examples

Mild wear and tear in a manual transmission often manifests as subtle changes that might not immediately indicate a major problem. These signs are typically less disruptive to the driving experience and may be overlooked.

- Gear Shifting Noise: A slight grinding or clicking sound, particularly when shifting from one gear to another, may be a sign of early wear on the synchronizers. This noise usually occurs only at certain speeds and/or gear combinations.

- Slight Play in the Shift Linkage: A small amount of play in the shift lever or linkage can occur due to wear in the bushings or bearings. This may feel like a slightly loose or imprecise gear shift, but the vehicle is still drivable.

- Decreased Clutch Engagement Smoothness: The clutch may require a slightly firmer or longer engagement. The pedal might feel slightly stiffer than normal, without significant slipping or resistance during operation.

- Minor Oil Leaks: A tiny oil leak, often in the form of a few drops, may indicate a minor seal issue that hasn’t yet progressed to a major leak. This is often accompanied by a slight change in the transmission fluid level.

Severe Wear and Tear Examples

Severe wear and tear signals a more significant issue and could lead to substantial repair costs or even transmission failure. These symptoms are more noticeable and can negatively affect the vehicle’s drivability.

- Loud Grinding or Scraping Sounds: A loud grinding or scraping noise, especially during shifting, signifies substantial damage to synchronizers or other internal components. This noise will be more persistent and severe than the minor noises associated with mild wear.

- Significant Play in the Shift Linkage: Excessive play in the shift lever or linkage, potentially causing a significant looseness in the gear shift, suggests significant wear in the linkage components, including the bearings and bushings.

- Clutch Pedal Sticking or Difficulty Engaging: The clutch pedal may exhibit resistance, stick, or be exceptionally difficult to depress or release, indicating severe wear in the clutch system.

- Large Oil Leaks: A substantial oil leak from the transmission, possibly accompanied by puddles under the vehicle, indicates a severe seal failure or damage to internal components.

Common Damage Examples

Common damage in manual transmissions often stems from neglecting maintenance or driving habits. These examples highlight situations that require immediate attention.

- Synchronizer Ring Damage: Visible damage to the synchronizer rings, such as scoring or chipping, can lead to difficulty shifting gears. This damage may be accompanied by a loud grinding noise.

- Gear Meshing Problems: Bent or damaged gear teeth in the transmission gears can cause problems with gear engagement, leading to difficulty in shifting or a rough shifting experience. This can manifest as loud noises and/or grinding.

- Bearings and Bushings Failure: Damage or failure of bearings and bushings, essential for smooth operation, can lead to a significant amount of play in the linkage, making shifting difficult and noisy.

- Internal Bearing Damage: Internal bearings failing can cause significant noise during operation. The noise will typically increase with speed and/or gear selection.

Table of Wear and Tear Examples

| Component | Mild Wear | Severe Wear | Damage |

|---|---|---|---|

| Synchronizers | Slight clicking/grinding when shifting | Loud grinding/scraping when shifting | Bent/broken synchronizer rings |

| Shift Linkage | Slight play in shift lever | Excessive play, loose linkage | Broken linkage components |

| Clutch | Slightly firmer engagement | Sticking, difficulty engaging | Damaged clutch disc/pressure plate |

| Bearings/Bushings | Minor looseness in linkage | Significant looseness in linkage | Broken/damaged bearings/bushings |

| Gears | N/A | N/A | Bent/broken gear teeth |

| Seals | Minor oil leak | Large oil leak | Damaged seals |