Introduction to Manual Gearboxes

Understanding the different types of car manual gearboxes – Manual transmissions, commonly referred to as manual gearboxes, are a fundamental component of many vehicles, offering drivers a direct connection to the engine’s power. They provide a tangible driving experience, allowing for precise control over acceleration and deceleration, and often are preferred for their fuel efficiency in some driving scenarios. This control is achieved through the manual selection of different gear ratios, which directly impact the vehicle’s speed and torque output.The fundamental principle of a manual gearbox lies in its ability to alter the gear ratio between the engine and the drive wheels.

This alteration allows for a smooth and controlled power delivery, adapting to varying road conditions and driver needs. Different gear ratios provide different levels of torque and speed, allowing the driver to choose the optimal gear for a given situation.

Essential Components of a Manual Gearbox

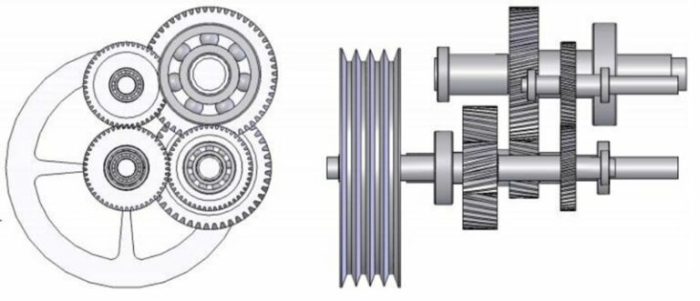

A manual gearbox comprises several crucial components working in concert. These components include a gear train, a clutch, a gear selector, and a synchronizer. The gear train is a series of gears with varying sizes, enabling different gear ratios. The clutch disconnects the engine from the gearbox, allowing for smooth gear changes. The gear selector enables the driver to select the desired gear.

Synchronizers ensure smooth gear changes by matching the rotational speed of the input and output shafts before engaging the gears.

Types of Manual Gearboxes

Manual gearboxes are categorized based on various design characteristics and functionalities. Understanding these categories provides insight into the specific engineering trade-offs and intended use cases.

| Type | Description | Common Features |

|---|---|---|

| Standard Manual Transmission | The most common type, featuring a simple gear arrangement and a mechanical clutch. | Straightforward operation, generally affordable to manufacture, and offers direct engine control. |

| Sequential Manual Transmission (SMG) | A semi-automatic transmission that utilizes a clutch mechanism, but the gear changes are controlled by the driver via paddles or a gear selector. | Enhanced driver control, allowing for quick gear changes, and often providing a sportier driving experience. |

| Automated Manual Transmission (AMT) | This system utilizes a clutch mechanism but employs an automated system to manage gear changes. The driver can still manually select gears if desired. | Combination of manual and automatic features, often offering better fuel efficiency than a standard manual transmission due to automated gear changes in certain driving scenarios. |

Types of Manual Gearboxes

Manual transmissions, a fundamental component of many vehicles, come in various configurations. Understanding these differences is crucial for appreciating the engineering trade-offs involved in their design and for choosing a suitable transmission for specific applications. This section delves into the common types of manual gearboxes, examining their characteristics, and design elements.

Common Manual Transmission Types

Different manual transmissions are designed with varying numbers of gears, each impacting the vehicle’s performance and efficiency. Common types include 4-speed, 5-speed, and 6-speed transmissions. The number of gears directly affects the range of speeds achievable and the overall driving experience.

Gear Ratio Characteristics

The gear ratios in a manual transmission are fundamental to its function. These ratios dictate the relationship between the engine’s rotational speed and the wheels’ rotational speed. A lower gear ratio provides greater torque, enabling acceleration and hill climbing, while higher gear ratios enhance speed and fuel efficiency at cruising speeds. The specific gear ratios vary between different transmission types, influencing the vehicle’s overall performance.

Design Differences

The design of a manual gearbox involves several key elements. The number of gears, the gear ratios, and the presence of synchronizers significantly affect the gearbox’s performance and the driver’s experience.

Number of Gears

The number of gears directly impacts the range of speeds available to the driver. A gearbox with more gears allows for smoother transitions between different speeds and a broader range of performance characteristics. For example, a 6-speed transmission typically provides a wider range of gear ratios than a 4-speed, allowing for better fuel efficiency at highway speeds and enhanced acceleration in lower gears.

Gear Ratios, Understanding the different types of car manual gearboxes

Gear ratios are crucial in determining the relationship between the engine’s rotational speed and the wheels’ rotational speed. Different ratios are required for different driving situations, with lower ratios providing more torque for acceleration and higher ratios improving fuel efficiency at higher speeds.

Synchronizers

Synchronizers are crucial components within manual transmissions. They ensure that the gears mesh smoothly, preventing damage to the transmission. They function by matching the rotational speed of the input and output shafts before engaging gears. This crucial mechanism prevents gear clash and wear, ensuring smooth and safe gear changes.

Comparison Table

| Transmission Type | Number of Gears | Typical Gear Ratios | Performance Characteristics |

|---|---|---|---|

| 4-speed | 4 | (Example) 2.80, 1.60, 1.00, 0.75 | Suitable for basic driving, adequate acceleration but less fuel efficient. |

| 5-speed | 5 | (Example) 3.30, 2.00, 1.30, 1.00, 0.70 | Improved fuel efficiency and acceleration compared to 4-speed, wider range of driving conditions. |

| 6-speed | 6 | (Example) 3.80, 2.30, 1.50, 1.00, 0.80, 0.60 | Excellent fuel efficiency, wide range of performance characteristics, allowing for better fuel economy at highway speeds. |

Gear Ratios and Shifting Mechanisms: Understanding The Different Types Of Car Manual Gearboxes

Source: augustman.com

Understanding gear ratios and shifting mechanisms is crucial for optimizing vehicle performance and fuel efficiency in a manual transmission. Proper shifting technique not only enhances the driving experience but also minimizes wear and tear on the transmission components. This section delves into the intricacies of gear ratios, their impact on speed and acceleration, and the importance of skillful shifting techniques.Gear ratios directly influence how a vehicle accelerates and maintains speed.

A lower gear ratio allows for greater torque output, ideal for accelerating from a standstill or climbing steep inclines. Conversely, higher gear ratios result in higher speeds with lower torque output, enabling efficient cruising at highway speeds. Understanding this relationship between gear ratio and performance is essential for effective driving.

Gear Ratios and Vehicle Performance

Gear ratios are the fundamental relationship between the engine’s rotational speed and the wheels’ rotational speed. A lower gear ratio means the engine turns faster than the wheels for a given speed. This translates to higher torque, enabling acceleration and hill climbing. Conversely, a higher gear ratio results in the engine turning slower than the wheels, yielding higher speeds with less torque, crucial for maintaining speed on the highway.

For instance, a lower gear like first gear provides maximum torque for rapid acceleration, while a higher gear like fifth gear enables higher speeds with less engine load, promoting fuel efficiency.

Importance of Proper Shifting Techniques

Proper shifting techniques are paramount for optimal performance and longevity of the transmission. Smooth and timely shifts reduce wear and tear on the transmission components, enhancing their lifespan. Rough or delayed shifts can cause damage to gears and synchronizers, leading to costly repairs. The driver’s skill in matching the engine’s speed to the gear ratio is key to a smooth and efficient driving experience.

Relationship Between Gear Ratios and Speed

Gear ratios and vehicle speed have a direct relationship. Lower gear ratios translate to lower speeds but higher torque, suitable for situations demanding high torque output, like accelerating from a standstill. Higher gear ratios yield higher speeds with less torque, ideal for maintaining speed on highways. The driver must select the appropriate gear based on the vehicle’s speed and the driving situation to optimize performance.

For example, a car in first gear is at a low speed but has maximum torque to accelerate, whereas a car in fifth gear is at a high speed but with less torque.

Gear Shifting Mechanism Diagram

A simplified diagram illustrating the gear shifting mechanism in a manual gearbox:

| Component | Description |

|---|---|

| Gearbox Housing | Encloses the gears and shifting mechanism. |

| Gears | Interconnected toothed components, each with a specific gear ratio. |

| Shift Fork | Connects to the gear lever and moves the gears into position. |

| Synchronizers (Optional) | Match the speed of the input and output shafts before engagement. |

| Shift Linkage | Connects the gear lever to the shift fork. |

[Illustrative Diagram (Conceptual): A simple, block diagram showing the gearbox housing, gears, shift fork, and shift linkage connected to a gear lever. Arrows indicate the movement of the shift fork during gear changes.]

This diagram illustrates the basic components involved in changing gears. The shift lever’s movement through the linkage activates the shift fork, which in turn positions the appropriate gear to mesh with the input shaft, facilitating gear changes.

Proper engagement of gears is crucial to ensure smooth and efficient operation of the transmission.

Advantages and Disadvantages of Manual Gearboxes

Source: washtenaw211.org

Manual transmissions, while becoming less common, still offer a unique driving experience and specific advantages for certain drivers and situations. Understanding their strengths and weaknesses compared to automatics is crucial for making an informed choice.Manual gearboxes provide a direct connection between the engine and the wheels, allowing for precise control over the vehicle’s power delivery. This direct connection, along with the opportunity to shift gears, offers a level of engagement and control that some find inherently satisfying.

Benefits of Manual Transmissions

Manual transmissions offer several compelling advantages. The driver’s active participation in controlling the power flow through the transmission leads to a heightened sense of control and engagement with the vehicle. This connection allows for optimal fuel efficiency in certain situations.

- Enhanced Fuel Efficiency: In certain driving conditions, a skilled driver can achieve better fuel economy with a manual transmission. The driver can select the gear that best suits the current speed and load, avoiding unnecessary engine braking or acceleration. For example, in highway driving, selecting a higher gear at a steady speed reduces engine load and thus fuel consumption compared to an automatic transmission unnecessarily maintaining a lower gear.

- Improved Responsiveness and Control: Manual transmissions offer immediate and precise control over acceleration. The driver can adjust to various driving situations, like steep inclines or rapid acceleration, by selecting the appropriate gear. This responsiveness and control are absent in automatics, which sometimes delay the delivery of power.

- Lower Cost: Generally, manual transmission vehicles have a lower initial purchase price compared to their automatic counterparts. This can be a significant factor for budget-conscious buyers.

Drawbacks of Manual Transmissions

Despite their benefits, manual transmissions also have limitations. The need for constant gear shifting can be a distraction for some drivers, especially in traffic or when navigating challenging road conditions.

- Higher Skill Requirement: Driving a manual car requires a greater level of skill and practice. Learning to coordinate clutch operation with gear shifting takes time and effort, and some drivers may find this process cumbersome.

- Driver Fatigue: Constant gear shifting, particularly during prolonged driving, can lead to driver fatigue. This can be especially challenging in heavy traffic or during long commutes.

- Less Convenient in Certain Conditions: Manual transmissions can be less convenient in situations where frequent stops and starts are required. The constant shifting can be distracting or time-consuming in stop-and-go traffic.

Manual vs. Automatic Transmissions

Comparing manual and automatic transmissions reveals distinct advantages and disadvantages for each. The choice often comes down to individual preferences and driving styles.

| Feature | Manual Transmission | Automatic Transmission |

|---|---|---|

| Control | High level of control over power delivery and fuel efficiency. | Less control over power delivery; easier to drive in stop-and-go traffic. |

| Skill Required | Requires learning and practice to master. | Generally easier to learn and operate. |

| Cost | Often lower initial purchase price. | Often higher initial purchase price. |

| Fuel Efficiency (Potential) | Potentially higher in skilled hands and appropriate driving conditions. | Generally more fuel-efficient at higher speeds. |

| Driver Fatigue | Potentially higher in certain situations, especially in stop-and-go traffic. | Lower fatigue levels in stop-and-go driving. |

Maintenance and Troubleshooting

Maintaining a manual gearbox requires regular attention to ensure smooth operation and longevity. Proper maintenance can significantly extend the life of the transmission and prevent costly repairs. Troubleshooting common problems early can also save time and money. This section details the necessary procedures and common issues to help you keep your manual transmission running efficiently.

Essential Maintenance Procedures

Regular maintenance is crucial for preventing major problems with manual gearboxes. These procedures should be followed to maintain optimal performance and longevity.

- Fluid Changes: Regular fluid changes are vital. The frequency of these changes depends on the vehicle manufacturer’s recommendations, typically every 30,000 to 50,000 miles, or as specified in the owner’s manual. Using the correct type and amount of transmission fluid is paramount. Improper fluid can lead to premature wear and tear on internal components.

- Gearbox Inspection: Periodic inspections for signs of wear or damage are recommended. Check for leaks, unusual noises, and any signs of damage to the external components. This proactive approach can help identify problems before they escalate.

- Clutch Adjustment: A properly adjusted clutch is essential for smooth shifting. The clutch should be inspected and adjusted if necessary, according to the vehicle’s specific instructions. Incorrect clutch adjustment can lead to slipping or difficulty engaging gears.

- Shift Linkage Inspection: The shift linkage is responsible for transferring the driver’s input to the gearbox. Regular inspection of the linkage for proper alignment and lubrication is important. Any issues with the linkage can affect shifting accuracy and smoothness.

Common Transmission Problems

Several issues can arise in manual transmissions. Prompt identification and resolution are essential.

- Gear Grinding or Jumping: This often indicates problems with the synchronizers, gears, or the input shaft. Grinding sounds usually accompany problems with gear engagement. Jumping can result from worn synchronizers or issues with the clutch.

- Difficulty Shifting: Difficulty shifting can be due to worn or damaged synchronizers, or issues with the shift linkage. The linkage should be inspected for proper alignment and lubrication.

- Clutch Problems: Clutch slippage is a common issue. This can be caused by worn clutch plates, friction material, or pressure plate. It can also result from improper clutch adjustment.

- Leaks: Transmission fluid leaks can cause low fluid levels, leading to overheating and component damage. The source of the leak should be identified and repaired immediately. Leaks can originate from seals, gaskets, or damaged housing.

Troubleshooting Procedures

Accurate diagnosis is crucial for effective repair. A systematic approach can aid in pinpointing the problem.

- Initial Assessment: The first step involves carefully assessing the symptoms. Note the specific nature of the problem, such as the type of noise, the gears affected, or the presence of leaks. This initial observation helps narrow down potential causes.

- Visual Inspection: A visual inspection of the transmission components for any visible damage or wear is crucial. Inspect the fluid level, and look for leaks or unusual noises.

- Diagnostic Tools: Diagnostic tools, such as a torque wrench or a pressure gauge, might be required for accurate diagnosis. These tools can help to identify problems in the clutch and linkage systems.

- Consult the Owner’s Manual: The vehicle’s owner’s manual provides crucial information about the specific maintenance and troubleshooting procedures for the manual gearbox.

Tools and Equipment

The following tools and equipment may be necessary for maintenance and troubleshooting.

- Torque wrench

- Transmission fluid

- Socket set

- Wrench set

- Drain pan

- Gloves

- Jack stands

- Safety glasses

Historical Context and Evolution

Source: autoprotoway.com

Manual transmissions, a cornerstone of automotive technology, have a rich history intertwined with the development of the internal combustion engine. Their evolution reflects a continuous quest for efficiency, performance, and driver engagement. Early designs, while rudimentary, laid the foundation for the sophisticated gearboxes found in modern vehicles.

Early Manual Transmissions

The initial designs of manual transmissions were simple, often employing a few gears to accommodate varying driving conditions. These early systems focused on achieving basic functionality, with minimal attention to fine-tuning or advanced features. Early automobiles often featured simple lever-operated gearboxes, which allowed for shifting between different gear ratios. The design of these early gearboxes prioritized simplicity over complexity.

Evolution of Design

Over time, significant advancements in manual transmission design were introduced. These innovations aimed to enhance performance, durability, and driver comfort. Improvements included refined gear ratios, optimized shifting mechanisms, and enhanced materials for greater longevity. The incorporation of synchromesh systems allowed for smoother gear changes, mitigating the jarring shifts often experienced in older models.

Key Innovations

Several key innovations have shaped the evolution of manual transmissions. The introduction of synchromesh systems was a significant leap forward, enabling smooth and controlled gear changes across a wider range of vehicle speeds. Improvements in gear tooth profiles enhanced gear engagement and reduced wear. The use of stronger materials and more sophisticated manufacturing processes contributed to the robustness and durability of these systems.

Furthermore, advancements in manufacturing processes resulted in lighter and more efficient transmissions.

Timeline of Manual Transmission Evolution

| Year | Innovation | Impact |

|---|---|---|

| Early 1900s | Basic gearboxes with levers | Enabled the transition of vehicles from basic functionality to wider adoption. |

| 1920s-1930s | Refinement of gear ratios and shifting mechanisms | Increased performance and driver engagement. |

| 1940s-1950s | Introduction of synchromesh | Improved the driver experience by reducing the effort and impact of gear changes. |

| 1960s-1970s | Advanced materials and manufacturing processes | Enhanced durability and reduced weight, contributing to overall vehicle efficiency. |

| 1980s-2000s | Compact and lightweight designs | Further improved fuel economy and vehicle performance. |

| Present | Continued refinement in materials, gear ratios, and shifting mechanisms. | Continued optimization to balance performance and efficiency. |

Specific Transmission Types (e.g., synchromesh)

Synchromesh transmissions represent a significant advancement in manual gearboxes, enhancing the driver experience by enabling smoother and more precise gear changes. These systems overcome the challenges of shifting between gears without the need for a significant amount of force, particularly at lower speeds. This is crucial for both comfort and safety, especially in urban driving and when making quick maneuvers.A key feature of synchromesh transmissions is the mechanism that synchronizes the rotational speed of the input and output shafts before engaging a gear.

This allows for a seamless transition between gears, eliminating the jarring sensations associated with traditional non-synchromesh transmissions.

Operation of a Synchromesh Transmission

The operation of a synchromesh transmission centers around the precise synchronization of the input and output shafts’ rotational speeds. This is achieved through a friction ring, or synchronizer, which engages with the gear teeth to ensure the correct rotational speed before the gear meshing occurs. As the driver shifts, the synchronizer ring gradually brings the speed of the output shaft into alignment with the input shaft’s speed, ensuring a smooth gear change.

Components of a Synchromesh Transmission

The primary components of a synchromesh transmission include:

- Synchronizer Rings: These are the critical components that match the rotational speeds of the input and output shafts. They consist of a friction material that engages and disengages to adjust speed, ensuring a smooth gear change.

- Gears: The gears themselves, with their precise tooth profiles, are essential for power transmission. Their precise design and material selection are critical for reliability and durability.

- Shift Fork: This component is responsible for engaging the synchronizer ring and controlling the shifting mechanism. Its precise design and operation are vital for the overall efficiency and precision of the transmission.

- Shift Drum: This housing component guides the shift fork, ensuring the proper movement of the gear selector lever.

Examples of Vehicles Using Synchromesh Transmissions

Synchromesh transmissions have been a standard feature in numerous vehicles over the decades. Examples include:

- Many popular passenger cars: From compact models to larger sedans, synchromesh transmissions are common in vehicles designed for passenger transport. The prevalence of this design underscores its efficacy and broad applicability.

- Light trucks and SUVs: The robustness and smooth shifting characteristics make synchromesh transmissions a suitable choice for vehicles needing to handle varying loads and driving conditions.

Comparison to Other Transmission Types

Synchromesh transmissions stand apart from non-synchromesh designs by providing a noticeably smoother shifting experience. Traditional non-synchromesh transmissions often require significant force to shift gears, particularly when the speeds of the input and output shafts differ significantly. This difference in operation translates to a more substantial shift effort for the driver.

Modern Applications and Trends

Manual gearboxes, despite the rise of automatic transmissions, continue to hold a significant place in the automotive landscape. Their inherent simplicity, engaging driving experience, and efficiency in specific applications ensure their continued relevance. This section explores the current uses of manual transmissions and the anticipated future of this technology.

Current Applications

Manual transmissions remain prevalent in certain vehicle segments and applications. Their continued popularity stems from a combination of factors, including cost-effectiveness and driver engagement.

- Performance Vehicles: Manual gearboxes are still highly sought after in performance-oriented vehicles. The direct control over power delivery, and the feeling of engagement, appeal to enthusiasts who value the tactile interaction with the vehicle.

- Off-Road Vehicles: The ruggedness and reliability of manual transmissions make them a practical choice for off-road vehicles. Their simplicity and ability to handle demanding conditions make them suitable for navigating challenging terrains.

- Budget-Conscious Vehicles: Manual gearboxes often represent a more economical choice in vehicles with lower price points. This cost-effectiveness is often a key consideration for manufacturers targeting price-sensitive markets.

- Racing Applications: The precise control and responsiveness of manual transmissions remain paramount in racing. The ability to instantly adjust gear ratios is crucial for optimal performance on race tracks.

Future of Manual Transmissions

The future of manual transmissions in the automotive industry is likely to be nuanced, not simply a decline.

- Niche Market: Manual transmissions are expected to maintain a presence, but likely in a niche market focused on performance vehicles, enthusiasts, and specific applications.

- Hybrid and Electric Vehicles: While manual transmissions are less common in electric vehicles, some hybrid models may still incorporate them for certain purposes, especially for off-roading or performance features. The combination of electric power and manual control could be an attractive option.

- Specialized Vehicles: Certain specialized vehicles, such as agricultural equipment, construction vehicles, and some commercial trucks, may continue to rely on manual transmissions for their robustness and simplicity.

Factors Influencing Continued Popularity

Several key factors contribute to the ongoing appeal of manual transmissions.

- Driver Engagement: The direct connection between driver input and vehicle response offers a driving experience that many find engaging and rewarding.

- Cost-Effectiveness: Manual transmissions often have a lower manufacturing cost than automatic transmissions, which can be a significant factor for manufacturers and consumers in specific price brackets.

- Simplicity and Reliability: The fundamental design of a manual transmission is often simpler and more reliable than its automatic counterpart, resulting in reduced maintenance and repair needs.

- Fuel Efficiency: Modern manual transmissions, when paired with optimized engine tuning, can achieve comparable fuel economy to automatic transmissions in certain applications.

Trends in Specific Vehicle Segments

The prevalence of manual transmissions varies significantly across different vehicle segments.

- Sports Cars: Manual transmissions are a hallmark of many sports cars, emphasizing driver engagement and performance.

- SUVs and Trucks: Manual transmissions are less common in these vehicles, though they can still be found in some off-road-oriented or performance-tuned models.

- Compact Cars: The trend for manual transmissions in compact cars has fluctuated, and their presence depends on specific market conditions and manufacturer strategies.

Driving Experience and Skill Development

Mastering a manual transmission car requires a unique set of driving skills and a nuanced understanding of the vehicle’s mechanics. This section delves into the essential driving techniques and the progressive steps needed to become proficient. Beyond simply knowing the gear ratios, understanding the subtle interplay between clutch, throttle, and gear selection is key to a smooth and enjoyable driving experience.

Essential Driving Skills

Effective manual transmission driving goes beyond simply changing gears. It encompasses a coordinated approach to clutch control, throttle management, and gear selection. This holistic understanding allows for precise control of the vehicle’s acceleration and deceleration, leading to a safer and more controlled driving experience. Precise control, a key aspect of this, is vital in various driving scenarios, such as navigating tight turns or merging onto highways.

Clutch Control: The Cornerstone of Smooth Shifting

Clutch control is paramount to a smooth driving experience. It allows the driver to seamlessly transition between gears, preventing jerky movements and maintaining vehicle stability. Consistent practice in controlling the clutch is critical for building confidence and proficiency in driving a manual transmission vehicle.

Learning to Drive a Manual Transmission: A Step-by-Step Guide

Learning to drive a manual transmission requires patience and consistent practice. A structured approach, similar to learning any new skill, is crucial for developing proficiency.

- Initial Practice in a Controlled Environment: Begin in an open, safe area with minimal traffic. This allows for focused practice without the pressures of real-world driving. Focus on mastering the clutch and gear changes in a controlled environment before progressing to more complex scenarios.

- Gradual Acceleration and Deceleration: Once comfortable with basic gear changes, practice smooth acceleration and deceleration. Gradually increase the pressure on the accelerator while maintaining a steady release of the clutch. This helps refine control and minimizes jerky movements.

- Steering and Gear Coordination: Combine steering inputs with gear changes. This enhances coordination and allows for more controlled turns and maneuvers. Practice in different conditions, including slight turns and slow speed movements.

- Hill Starts and Stopping: Learning to start on hills and stop smoothly are critical. Practicing these maneuvers under controlled conditions is essential for safe and confident driving, as is understanding the nuances of hill starts and stops in various situations.

- Highway Driving and Merging: Practice driving on the highway and merging into traffic. This involves proper gear selection for highway speeds, and merging into traffic requires skillful anticipation of speed changes and traffic flow.

- Advanced Techniques and Troubleshooting: As proficiency improves, focus on advanced techniques, such as maintaining consistent speeds and adapting to different road conditions. Familiarize yourself with common troubleshooting procedures, like diagnosing and resolving minor issues.

Driving a Manual Car: A Step-by-Step Guide

This guide Artikels a methodical approach to driving a manual car, progressing from basic to advanced techniques.

- Starting the Vehicle: Engage the parking brake, put the car in neutral, and gently depress the clutch pedal. Turn the ignition key, and gradually release the clutch pedal while slowly pressing the accelerator pedal. The car should start smoothly.

- First Gear: Press the clutch pedal fully, select first gear, and slowly release the clutch while gently pressing the accelerator. The vehicle should start moving forward. Gradually increase the speed and practice the clutch and throttle coordination.

- Gear Shifting: To change gears, press the clutch pedal completely. Select the next gear and slowly release the clutch pedal while gently pressing the accelerator. Gradually increase the speed.

- Stopping the Vehicle: Press the clutch pedal completely. Select neutral gear and slowly release the clutch pedal. Apply the brakes gently to bring the vehicle to a complete stop.

- Braking: Use the brakes for slowing down and stopping. Avoid using the clutch for stopping. Combine clutch, throttle, and brakes for a smooth stop.